Three decades dedicated to the sector of heavy machinery moved by diesel in Brazil and in the world.

Reconditioning injection valves

Reconditioning of individual injection pumps

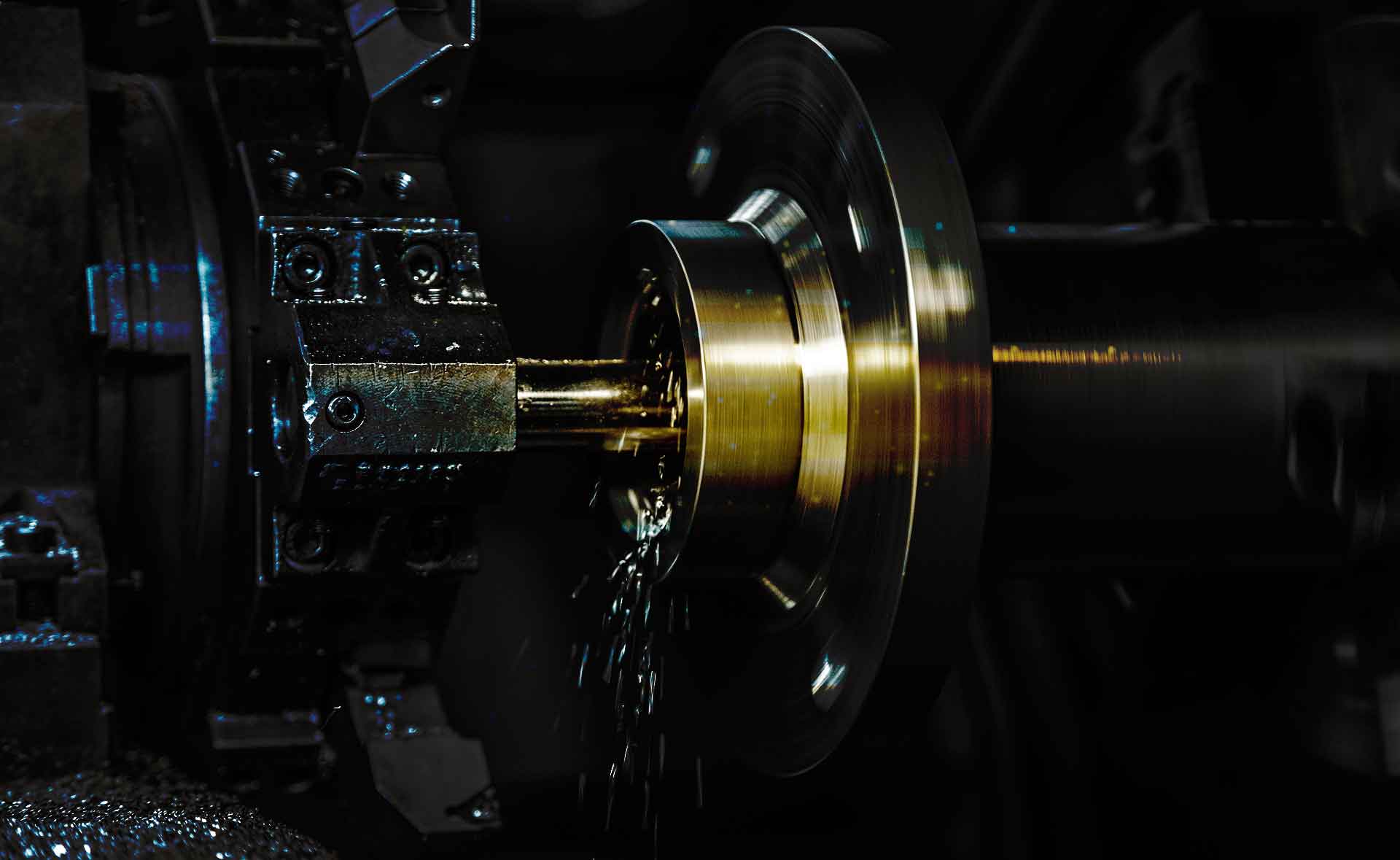

In Situ machining

Detailed technical reports

Committed to the quality of its services

INJTEC Injeção Diesel e Serviços Navais Ltda, was created in 1990 by engineers from the naval sector with extensive local and international experience, which ensured a rapid growth in the market for mechanical maintenance and ship repairs. Today, we are driven by diesel injection services for individual pumps.

INJTEC performs several machining operations in Brazil in situ for equipment of any activity.

INJTEC is a company ready to solve any emergency problems of diesel engines and heavy machinery anywhere, whether in the maritime, offshore, rail or industrial sector.

INJTEC is member of the ONIP-Oil Industry National Organization and ADS-Association of Diesel Specialists.

IN SITU MACHINING

Machining of crankshaft pins, with diameters from 80 to 450 mm

Crankshaft Performance

Grinding of crankshaft pins, with diameters from 80 to 450 mm

Machining and griding of thrust shaft bearing

Face grinding

Polishing of crankshafts, with diameters from 80 to 450 mm

Block Machining

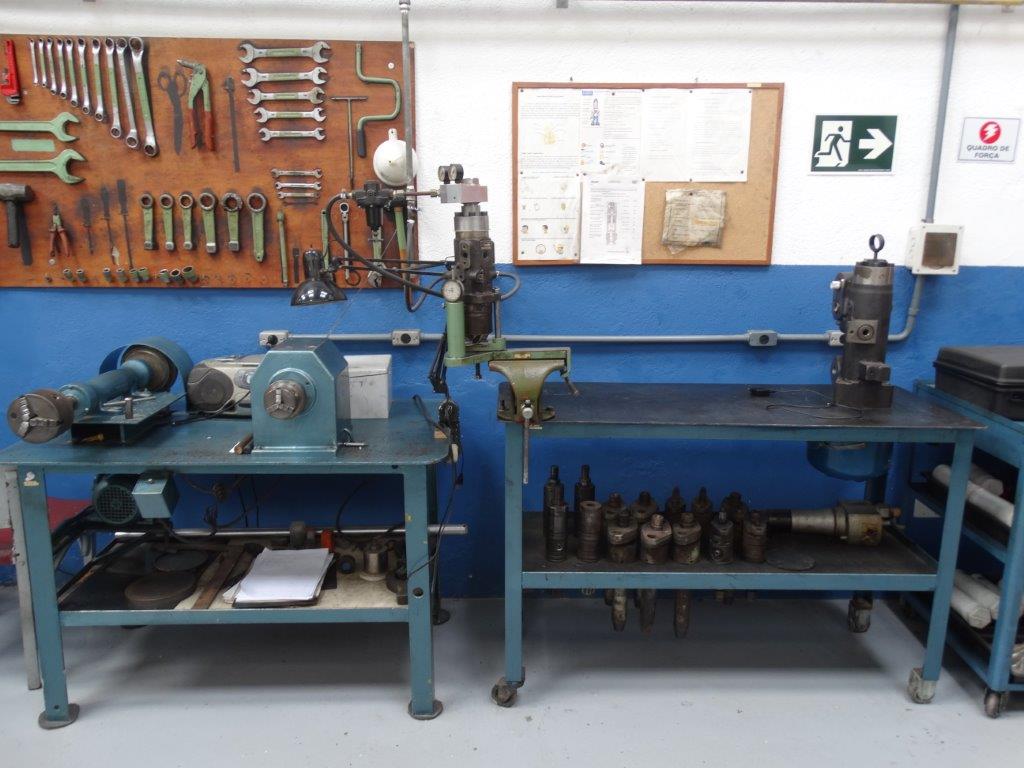

Our workshop

We have a team ready to attend in all corners of the country

For INJTEC only a Qualified Man with the right tools can provide top-quality services.

For this reason the company continuously invests in staff training and in modernizing and equipping its installations.

A laboratory of micrometrology, equipped with last generation tools, guarantees the precision of the executed services, from the adoption of internationally accepted technical parameters.

Budget?

We are available for information or questions

+55 21 2253-0500 | +55 21 98111-9761 (WhatsApp)

Contact Us

Information about the services, financial department and technical questions do not hesitate to send us a message.